SMD ASSEMBLY

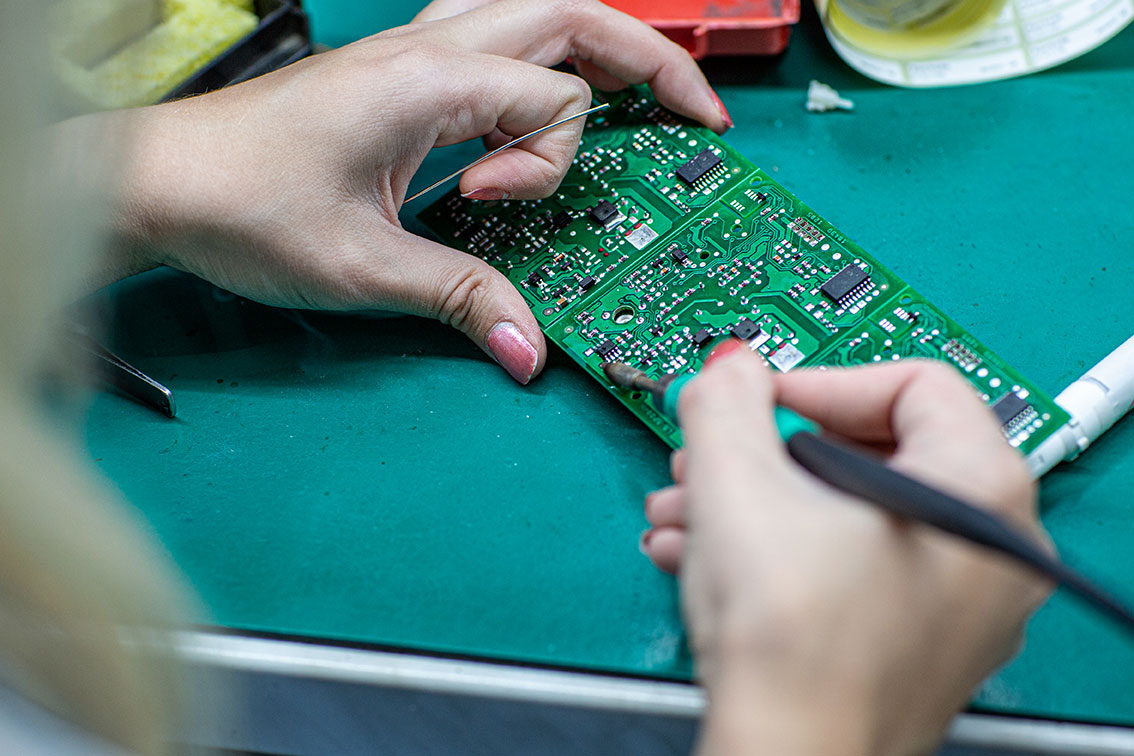

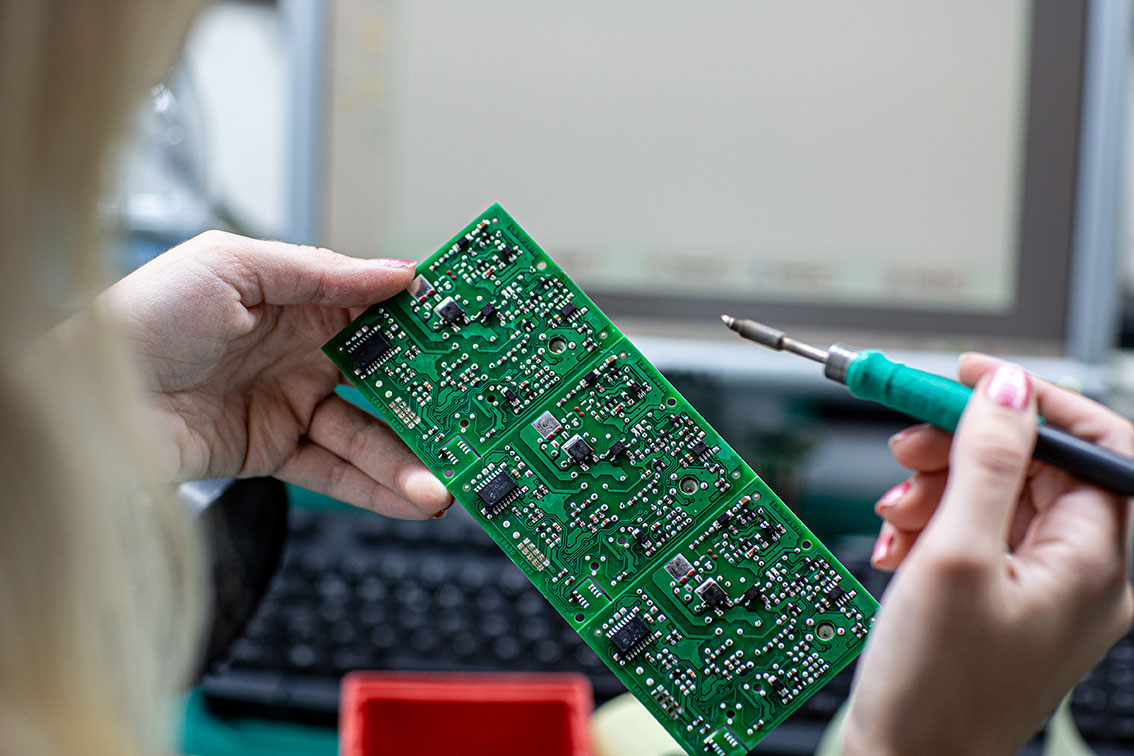

In SMD assembly, electronic components are soldered directly onto the copper surface of the board.

WHAT IS SMD PRINTED CIRCUIT BOARD ASSEMBLY?

The technical term SMD comes from electronics and stands for “surface-mounted device”.

In contrast to THT assembly, the electronic components are not mounted onto the PCB by means of wire connections, but are glued directly onto the PCB and then soldered.

The difference between SMD and SMT:

SMD assembly is nowadays the determining technology in the assembly of printed circuit boards.

AH! SMT is the abbreviation for “surface mounted technology”.

SMT thus refers to the technology behind the assembly of SMD boards. In practice, the two terms are used synonymously.

Advantages of SMD technology:

SMD components do not require wiring through drill holes in the board. Instead, the components are soldered directly onto the corresponding contact pads. This results in a significantly smaller space requirement than with conventional THT assembly. Associated advantages are:

- Ideal for circuits at high frequency

- Simplified production of small devices

- High packing density

- Double-sided assembly

- Reduced weight

- Faster production thanks to automated SMD assembly

- Higher quality

- Lower production costs

Disadvantages of SMD assembly:

- Since the design is very small, the labeling, which is stamped on the housing, is only possible by means of a code. The component function must be read out via this code.

- Soldering by hand is tricky and involves sources of error. A special soldering iron, tools and soldering material (solder, adhesive) are required. Hand soldering SMDs is easy to learn and can be done with good tools and some practice.

- Repairing defective devices with SMD components is rarely economical due to extremely small designs and dense packing. Therefore, devices are usually simply disposed of or the components are simply replaced.

SMD ASSEMBLY IN PROCESS

The assembly of the printed circuit board includes not only the placement of the components on the printed circuit board, but also the following work steps:

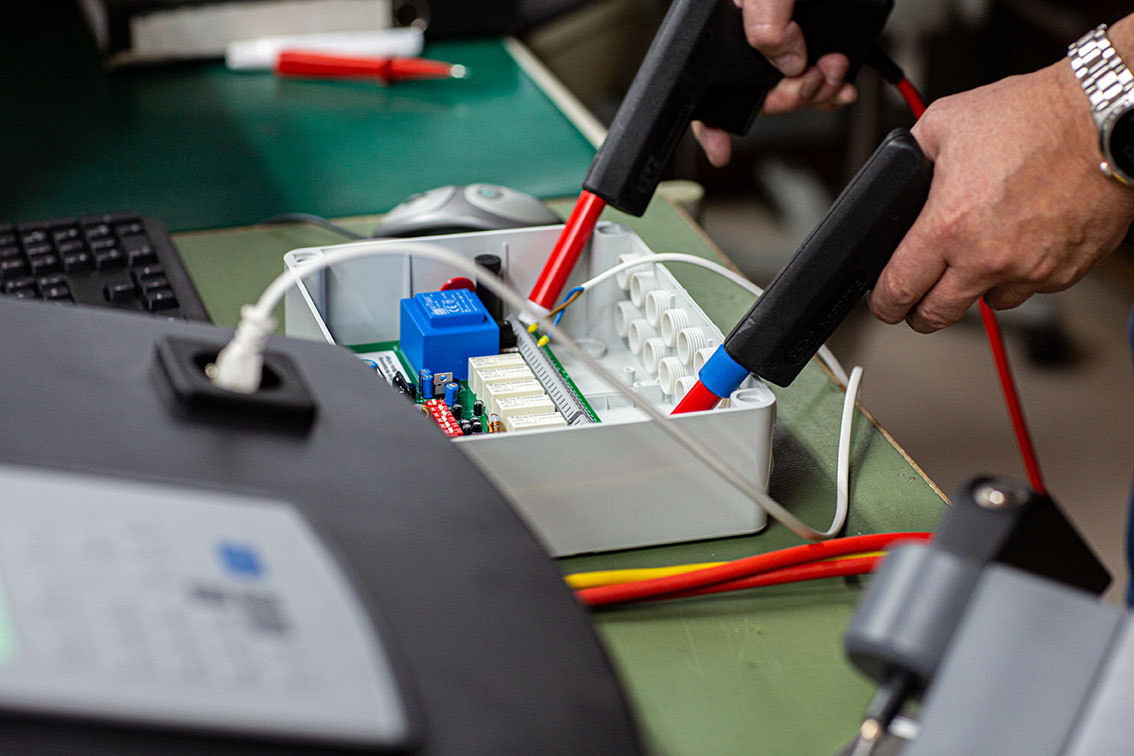

SMD ASSEMBLY AT STUHL

We assemble printed circuit boards in medium and large series

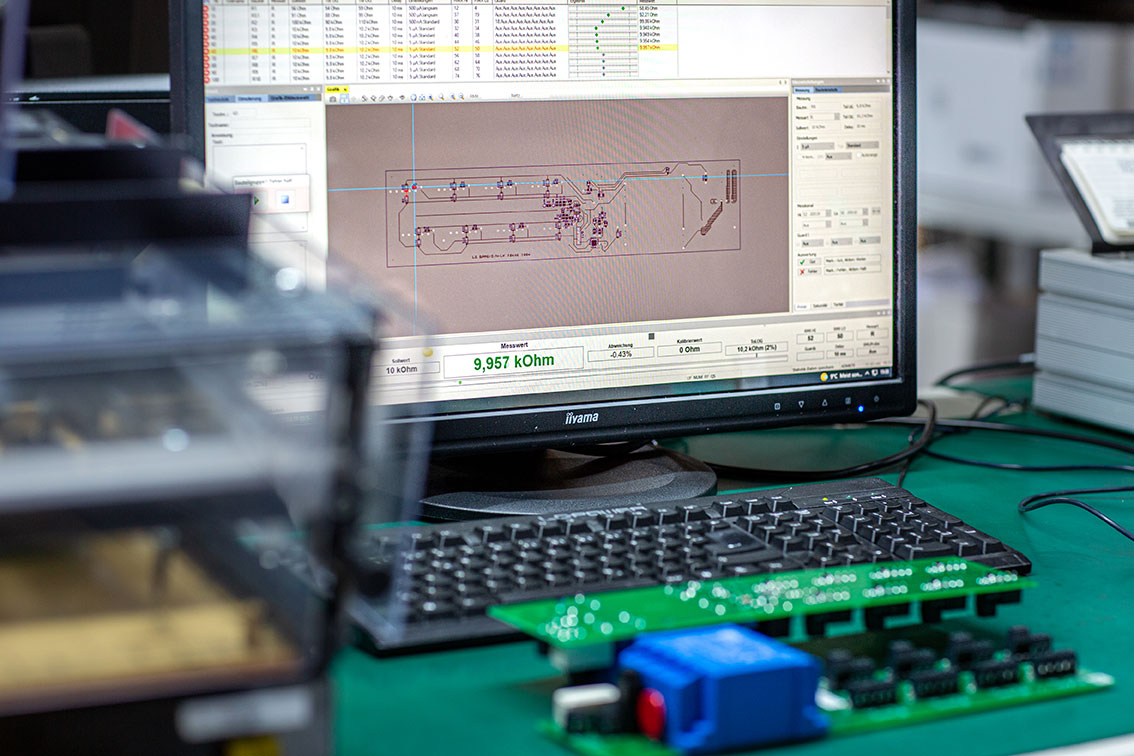

During production, we achieve high process and manufacturing quality with our state-of-the-art SMD manufacturing equipment.

ASSEMBLY PRECISION

xy µm

QFP GRID

up to xx mm

BGA GRID

up to xx mm

COMPONENTS PER H

from xxxx to xxxxx Bt/h

SMALLEST SMD COMPONENTxxxx

SOLDER PASTE PRINTING

xxx

THE SOLDERING OF THE COMPONENTS

Ideal soldering methods in SMD assembly

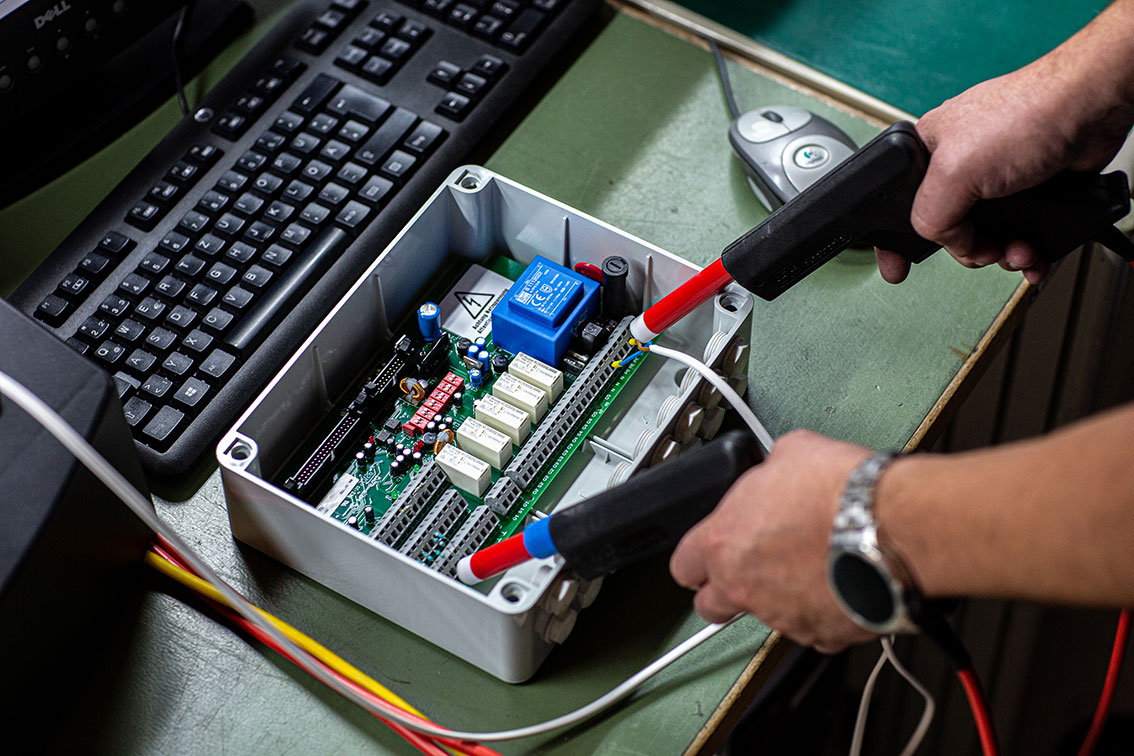

Circuits realized with SMD are often very compact. Due to the variety of components, high demands are placed on the soldering quality:

Reflow soldering

Reflow soldering is a common soft soldering process that is used in particular for soldering SMD components. In this process, printed circuit boards are printed with a solder paste using stencil printing. The individual components are placed on the boards using the pick-and-place method. The components adhere directly to the adhesive paste. The printed circuit board is then heated by full convection to a temperature high enough for the solder to melt and the SMD components to center and settle by themselves due to the surface tension.

Vapor phase soldering

For prototypes or highly sensitive components, vapor phase soldering is used, a separate vapor phase welding process. In this process, heating of the PCB in the SMD assembly is achieved by a controlled liquid vapor temperature (Galden). In this way, soldering can be performed more gently at lower temperatures and a uniform soldering temperature of each component can be ensured without a dip in the temperature profile.

Wave soldering

For double-sided SMD-equipped PCBs, the PCBs are printed with adhesive, the components are deposited into the adhesive, and the adhesive is cured using the reflow oven. The components are soldered together with the THT (Through Hole Technology) components in the wave soldering process. For various reasons, wave soldering of the SMD components is not always possible. In this case, the SMD components are soldered on both sides using the reflow process and THT components are soldered using the selective soldering process.

Areas where wired components cannot be replaced by SMD and components are still attached to the PCB using through-hole assembly are then soldered using a selective soldering system.See THT manufacturing.

What is an SMD assembler?

An SMD assembler is a machine used in the manufacturing of printed circuit boards.

AH!In SMD assembly, electronic components are placed on the surfaces of printed circuit boards with the help of an automatic placement machine.

WHAT SMD COMPONENTS DO WE HAVE?

SMD components include passive components such as resistors, capacitors and inductors. There are also integrated circuits and active components. The connectors and switches are also installed as SMD components on the circuit board.

PASSIVE COMPONENTS

(also diodes) are components that do not provide amplification and also have no control function. These are, for example, resistors, capacitors, inductors or quartzes and are manufactured and supplied in so-called chips. For special designs such as quartzes and oscillators, the package may have additional soldering areas.

ACTIVE COMPONENTS

are components which indicate a useful signal amplification or allow a control. These are e.g. transistors, optocouplers or relays.

Active components distinguish between packaging types that have either double-sided or four-sided solder pads.